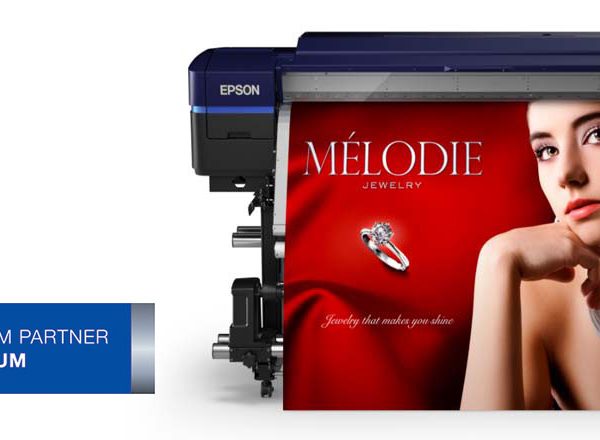

Wide Format Printers

Any computer-controlled printing machines (printers) that support a maximum print roll width of between 18″ and 100″ generally accepted as Wide format printers (large format printers).

The super-wide or grand format is considering Printers with capacities over 100″ wide.

To print banners, posters, trade show graphics, wallpaper, murals, backlit film (duratrans), vehicle image wraps, electronic circuit schematics, architectural drawings, construction plans, backdrops for theatrical and media sets, and any other large format artwork or signage are using Wide-format printers.

Wide-format printers usually employ some variant of inkjet or toner-based technology to produce the printed image. They are more economical than other print methods such as screen printing for most short-run (low quantity) print projects, depending on print size, run length (quantity of prints per single original), and substrate type.

Technologies

The type of ink transfer process they employ can be categorizing as Wide-format printers:

- Aqueous: Thermal or Piezo inkjet printers using an ink known as aqueous or water-based. Accepting misnomer is generally the term of water base. Kodak is using a non-reactive carrier solution that is sometimes water and other times a substitute liquid, including a soy-based liquid. Aqueous ink generally comes in two flavors, dye, and pigment. Dye ink is the high color, low UV-resistant variety that offers the widest color gamut. Pigment ink is generally duller in color, requiring more inks to achieve wide inks but withstands fading from UV rays. Similar in general principle to desktop inkjet printers. To protect the finished prints the outdoor, they must be laminating it. Various substrates (media) are available, including canvases, banners, plastic that metabolizing, and cloth. To accept and hold the ink are using material that can properly be coating is the requirement of aqueous technology.

- Solvent: To describe any ink that is not water-based—Piezo inkjet printers whose inks use petroleum is using this term. “Eco-Solvent” inks usually contain glycol esters or glycol ether esters and are slower drying.

- Dye sublimation: Inks are diffused into the unique print media to produce continuous-tone prints of photographic quality.

- UV: Piezo inkjet printers whose inks are UV-curable (dry when cured with UV light). The resulting prints are waterproof, embossed & vibrant. This technology can be using any media; polymer made media are best. Ceramics, glass, metals, and wood printing can be using this technology.

- Pen/plotter: To producing CAD drawings are using a pen or pens that can be use to draw on the print substrate. CAD drawings generally superseded by digital technologies such as Solvent, Aqueous, and UV.

Contact Us

Buy Wide Format Printers in Singapore